Adiabatic Humidifier Low-Energy Membrane Humidification

What is Adiabatic Humidification?

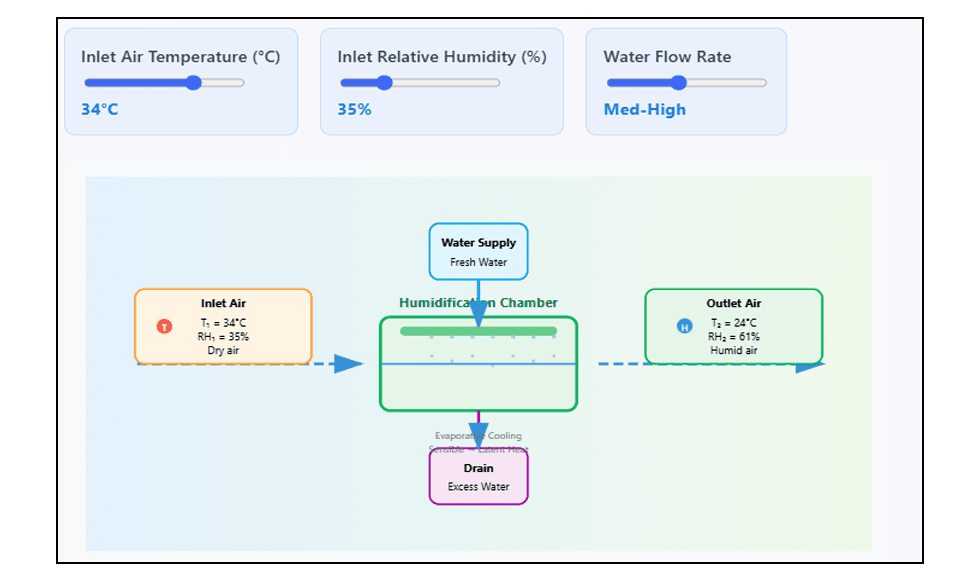

Adiabatic humidification is a smart way to add moisture to air. It uses cold water instead of hot water or steam. This process is called “adiabatic” because energy is required to change water from liquid to gas. The energy comes from the surrounding air as heat. This causes a decrease in temperature while adding humidity.

The system works through atomization and evaporation. Water provided as small droplets turns into vapor. This happens without using extra energy to heat the water first.

Adiabatic Humidification Example

How Does It Work?

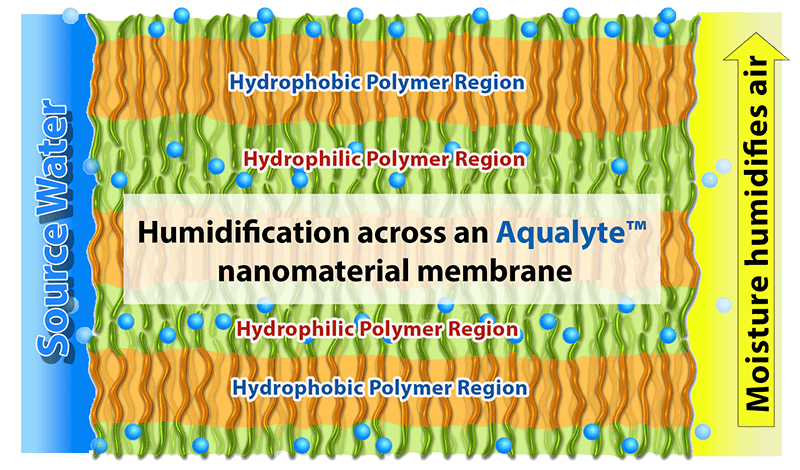

The system pumps cold water to one side of a special Aqualyte™ membrane. Air flows past the other side. Water molecules pass through the membrane quickly. They evaporate into the air stream.

The membrane is non-porous. This means bacteria and viruses cannot pass through. Even dissolved minerals and gases stay blocked. As tiny droplets evaporate, they pull heat from the surrounding air. This is called evaporative cooling or adiabatic cooling.

This process adds humidity without external heating. The energy consumption stays very low. The membrane is tough and lasts for the life of your equipment. No replacement is needed.

Click to See An Interactive diagram showing the cooling and humidification of air through water evaporation

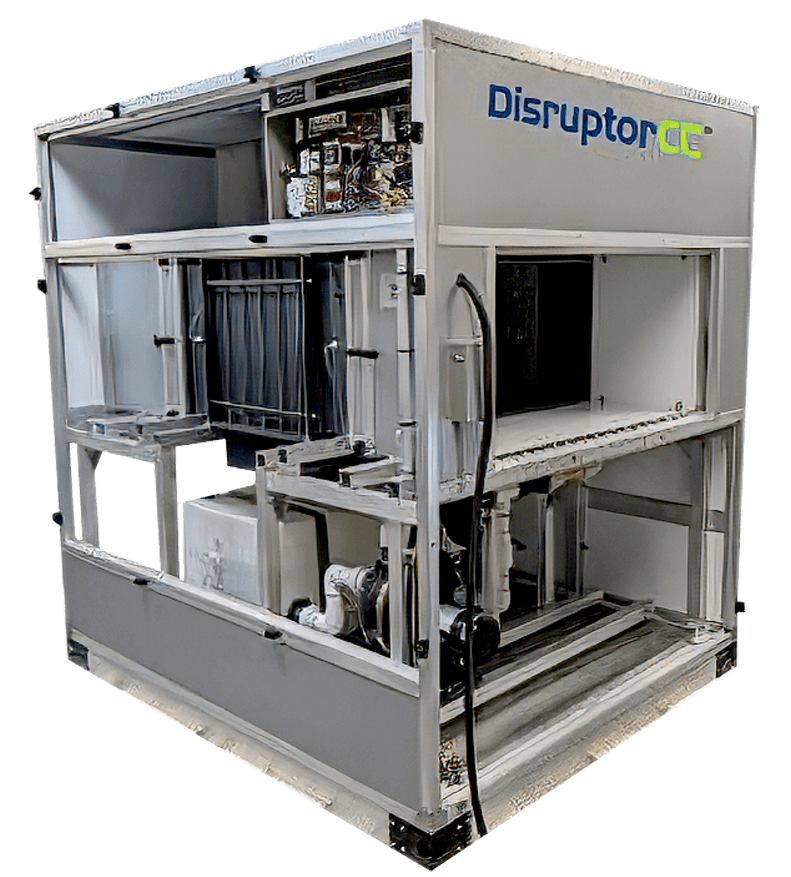

The DisruptorCC™ Membrane Humidifier

The DisruptorCC provides adiabatic humidification in a single unit. It works without water treatment systems. No microbes or minerals get released into the air. Wet surfaces do not form.

The system gives precise moisture control. This works separately from temperature control. Users report up to 94% savings in energy costs. Large manufacturing facilities see huge drops in operating expenses.

The Aqualyte™ membrane sits between water and air. It provides safe humidification without reverse osmosis (RO) or deionization (DI). The purchase price is competitive. Operating costs are the lowest in class. This means fast payback and low life cycle costs.

Key Advantages

- Low operating expenses and low CO2 emissions.

- No consumable components to replace.

- No water pretreatment required – use tap water without needing additional maintenance.

- No release of mineral dust or solids into the air.

- Scalable across building sizes and types.

- On-demand operation and rapid reaction to building needs.

- No wet surfaces or drains in the air stream and no microbial growth.

Case Study

A client with a DisruptorCC™ system in their manufacturing facility in the US shared they shut down two steam boilers previously operated year-round (even at the height of summer when there is rarely a humidification requirement) and replaced them with a much smaller system to cover their non-humidification needs.

Their system fills that gap with clean, sterile humidification on demand, regardless of the time of year, and when not needed it waits passively. By contrast, the steam boiler system had no shutdown mode, as the steam would condense into distilled water that rapidly corrodes the inside of the metal piping system. Instead, the boiler generated steam pressure and circulated year-round, consuming energy and turning it into a significant waste heat load on the building’s HVAC system.

The client has reduced their refrigeration load from 1,076 tons to less than 60 tons, a savings of more than 94%!

How It Compares to Other Systems

The DisruptorCC™ humidification system compared to other traditional humidifiers:

| Technology | Energy Costs $0.08/kWh | Operation | CAPEX 100 lbs/hr | OPEX 200,000 lbs./yr |

| DisruptorCC™ membrane humidification | $0.062 per 100 lbs. | Membranes last life of HVAC system. Sanitary, no viral or bacterial release. Tolerates tap or dirty water. No wet surfaces, drain pans in air duct. On-demand operation. Sanitary, no viral or bacterial release. Extensive distribution infrastructure. | $6,800-$9,500 (projected) | $123 energy $200-$300 maintenance |

| Steam Heat Exchanger | $1.80 per 100 lbs. | Mineral scales are manually cleaned from surfaces at regular intervals. High energy use at the boiler. Slow response to demand changes. | $5,100 | $1,000 $1,200 maintenance |

| Electric Canister Steam | $2.72 per 100 lbs. | On demand, no distribution losses. Highly uneven output from minute-to-minute & month-to-month. Replace disposable canisters every 3-6 months because of scale deposits. Highest energy costs. | $7,000 | $5,440 energy $1,200-$1,700 maintenance |

Cold-Water Fog | $0.05 per 100 lbs. | On-demand systems modulate output well. Requires RO water treatment system and maintenance. Wet surfaces in air duct. Typically , the droplet separator uses direct water that fails to evaporate to a drain. Low temperatures reduce but don’t eliminate bacterial threat. | $10,100 with RO system included | $100 energy $500-$800 maintenance |

| Ultrasonic | $0.30 per 100 lbs. | On-demand modulates output well. Requires DI water treatment to reduce mineral deposits in occupied spaces. Risk of bacterial growth & release. Does not scale well with size and requires many smaller units to achieve capacity. | $20,000-$25,000 with DI water system included | $640 energy $500-$800 maintenance |

Benefits for CEA and Vertical Farming Systems:

Low-energy adiabatic humidification systems are particularly well-suited for Controlled Environment Agriculture and vertical farming due to several key factors:

Precise Humidity Control:

Maintaining optimal humidity levels is critical for plant growth, preventing issues like mold, disease, and nutrient uptake problems.

Energy Efficiency:

CEA and vertical farming operations are highly energy-intensive. The significant energy savings (up to 90%) offered by adiabatic humidifiers directly reduce operational costs.

Non-Wetting Humidification:

Preventing water accumulation on plants, equipment, and surfaces is vital to avoid fungal growth, bacterial issues, and damage to electrical components.

Improved Air Quality:

By consistently maintaining humidity and potentially reducing airborne contaminants, these systems contribute to a healthier growing environment for plants.

Low Maintenance:

Many adiabatic systems are designed with few or no moving parts, reducing wear and tear and requiring infrequent maintenance, sometimes only every three years.

Versatility and Scalability:

They can be applied in various settings, from industrial processes to HVAC systems, and can be scaled for both small and large applications.

Want More Information?

Discover how we use Adiabatic humidification in our CEA Vertical Farming Systems and Solutions by clicking here.

You can also talk with one of our experts about your project or application requirements and see how Biz-Reps can help your organization.