Phase Change Insulation | ENRG Blanket

What are Phase Change Materials (PCMs)?

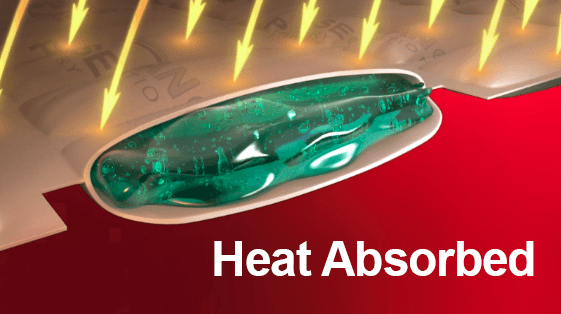

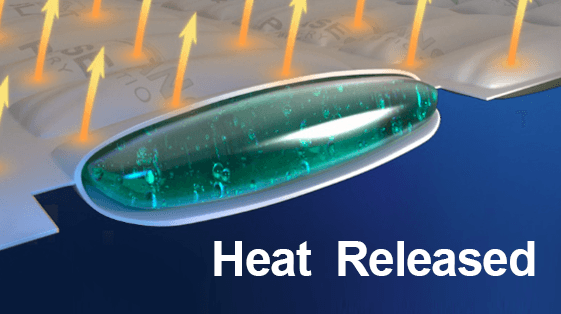

Phase Change Material (PCM) insulation is a substance that absorbs energy or releases energy during a phase transition to provide heating or cooling. This process allows the material to regulate indoor temperatures and enhance energy efficiency within a building.

During a phase change, molecules rearrange themselves and cause an entropy change that results in the absorption or release heat, meaning the temperature of the material itself remains constant as a great deal of energy is absorbed before melting, and released before freezing (absorb and store).

When heat is applied to a block of ice, the ice and resulting melted water remain at or near 32°F until the phase change is complete, (there is no more ice). The heat is absorbed as latent heat until the ice completely changes phase into water, (solid to liquid).

Conversely, when heat is removed from a pool of water, the temperature of the water and resulting ice will not fall below 32°F until the water completely changes phase into ice.

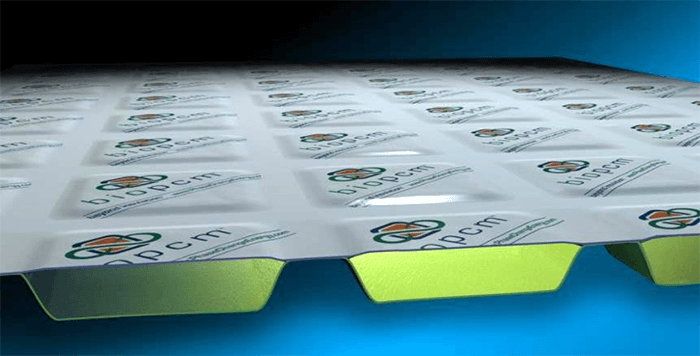

Microscopic BioPCM during a phase change transition

What is the ENRG Blanket?

ENRG Blanket is a proven and cost-effective means to reduce energy consumption. It works together with traditional HVAC units, reducing HVAC power consumption by 25-35%, run time by 15-20% and cycling frequency by 20-25% (depending on building type, orientation, age, location and equipment make and age) all while maintaining a consistent and stabilized temperature in accordance with industry standards.

In most locales, savings from ENRG Blanket will return its fully installed cost in less than four years, and in many cases less than three. Additional savings are realized through peak load shifting in locales that charge demand fees, increased HVAC life-expectancy and reduced maintenance and repair costs.

ENRG Blanket consumes no power and requires no maintenance to provide consistent power energy savings over its estimated useful life of more than 100 years.

By increasing efficiency, ENRG Blanket can help your team reduce operating expenses and free up resources to support growth, while also addressing global and corporate concern about the impact of power consumption on CO2 emissions, air pollution and climate change.

Technical Specifications

| SHEET SIZES & DESIGN OPTIONS | ENRG Blanket® products are shipped prefabricated in 24” x 48” sheets |

| COMMON DESIGN TEMPS | |

| ENRG Blanket Q23 | 23°C – 73°F |

| ENRG Blanket Q25 | 25°C – 77°F |

| ENRG Blanket Q273 | 27°C – 80°F |

| ENRG Blanket Q29 | 29°C – 84°F |

| SPECIFIC HEAT OF BIOPCM® | 2.0– 2.5 J/g°C |

| LATENT HEAT | 210 J/g (85/lb) |

| THERMAL STORAGE | 110 BTU/lb (255 J/g) |

| WEIGHT OF BLANKET | 0.6 to 1 lb/ft² |

| RECOMMENDED COVERAGE | 65-85% of conditioned square footage |

Fire Ratings

ENRG Blanket meets the following safety standards

| ASTM E84, UL 723, and CAN/ULC S102-10 | Standard test method for Surface Burning Characteristics of Building Material. |

| ASTM E800 | Standard guide for measurement of gases present or generated during fires. |

Phase Change Solutions earns USDA certified biobased product label with 100% biobased content. This certification verified that BioPCM® is composed of 100% biobased content.

Third-party verification for a product’s biobased content is administered through the USDA BioPreferred program

Types and Composition of PCMs

Phase Change ENRGY Blankets are available in two types:

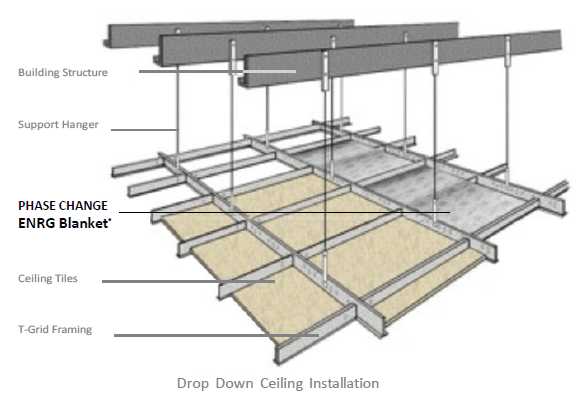

Drop Down Ceiling (Ceiling

Grids)

ENRG Blankets® may be installed over ceiling panels in new buildings or as a retrofit solution for existing buildings to lower HVAC demand. Blankets can also be installed in a single room or zones to mitigate “hot office syndrome.” Works well in high performing buildings with minimal disturbance to occupants.

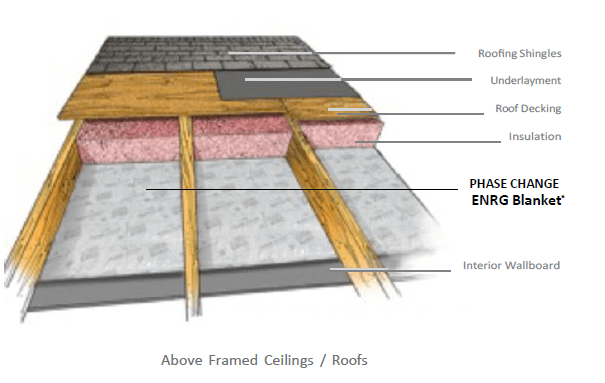

Above Framed Ceilings

ENRG Blanket® may be installed in new buildings and during renovations of interior spaces. It can be placed under framed ceilings, before drywall application, to lower energy demands for improved occupant comfort.

Benefits & Advantages

ENRG Blanket™ goes to work immediately to save energy by reduced HVAC cycling and reduce carbon emissions with thermal stability.

- Reduce reliance on HVAC equipment

- Reduces HVAC power consumption by up to 40% with reduced HVAC cycling thus reducing operating costs

- Reduce peak-demand

- Reduce CO2 emissions and your carbon footprint, Biopic reduced annual power consumption by more than 10,000,000 kWh — a CO2 emissions equivalent to 800,000 gallons of gasoline consumed or 7.5 million pounds of coal burned.

- Attractive payback period savings from ENRG Blanket will return to its fully installed cost in under four years in most cases.

- Improve building comfort by regulating indoor temperatures.

- The ENRG Blanket offers passive temperature control, requiring no power and no maintenance providing energy savings throughout its useful life of more than 100 years.

- Made from environmentally friendly, derived from naturally occurring, food grade substances

- Long life of performance, no degradation in melting temperature or thermal energy storage after thousands of freeze/melt cycles (100+ years)

- MADE in the USA, BioPCM is manufactured and packaged in Asheboro, NC.

ENRG BlanketTM 5-year comprehensive warranty

Phase Change Energy Solutions warrants its ENRG Blanket products, (including BioPCM®), to be free from manufacturing defects and defects in workmanship for a period of 5 years from date of sale. Additional terms and conditions apply. Please refer to complete warranty terms.

Application and Integration in Building Materials

PCMs are incorporated into building materials in the construction industry including building components like ceiling tiles. The large surface area of the ceiling plane is considered ideal for PCM placement.

The ENRG Blanket was designed as a retrofit to existing interior walls/ceiling with 24” x 20” rugged BioPCM® panels that quickly Snap in and out. The Installation can be completed in as little as 2 hours and require zero maintenance. The transition point can be tuned to customer specifications.

Because they add thermal mass back into the structure they can also be integrated into insulation products that are laid on top of existing attic insulation or suspended ceiling tiles. Some newer composites can even be added to building components and materials like paint or used as 3D-printable “ink” for building components installed in a diverse range of commercial and residential buildings.

Want More Information?

Talk with an expert about your project or application requirements